Revving Up Performance: Sustainability and Role of Investment Castings in Automotive Engineering

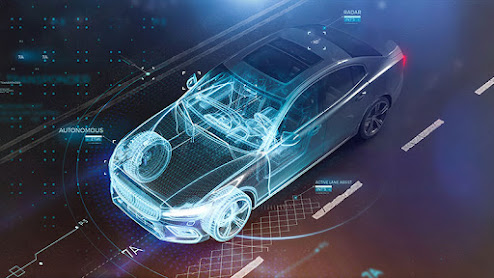

As and when the new technologies and materials are being developed on an annual basis, the automobile sector is continuously undergoing change. One of the most significant advancements that has taken place in the field of automotive engineering in recent years is the use of investment castings.

The manufacturing method known as investment casting enables the accurate fabrication of a wide variety of complicated shapes and forms. Because of this, it is an ideal alternative for automotive components that need to have high performance, extended durability, and reliable performance. Investment castings for automotive has developed into an essential component of the industry, as it enables automobile manufacturers to produce components of superior quality that are capable of satisfying the stringent standards of contemporary automobiles. Because of their capacity to make components with intricate geometries and superior material qualities, investment castings have traditionally been used exclusively in the aerospace and military industries.

The aerospace sector, in particular, reaps major advantages from investment casting since it provides increased opportunities for the production of very delicate components. Additionally, the automobile industry is able to save money and time via the use of investment casting for a wide variety of components, ranging from minor brackets to massive engine blocks and chassis parts. It is noteworthy that the medical sector has adopted investment casting for the manufacturing of prostheses and medical implants. This ensures that the creation of delicate components is carried out with tight standards and a high level of accuracy.

Investment Castings in the Automotive Industry: An Overview of Their Development

Over the course of many years, investment castings have been an essential component in the change that has taken place in the automobile industry. It has been a fascinating journey that has been distinguished by ongoing innovation and breakthroughs in the field of automobile engineering since investment castings have evolved over time.

Investment castings were first used for the production of elaborate jewelry and works of art. However, because to their capacity to create intricate and precise components with a high degree of accuracy, investment castings eventually made their way into the automobile industry. During the time when automobile engineers were looking for methods to increase fuel economy, decrease weight, and boost performance, investment castings emerged as a game-changing innovation.

Some Market challenges:

Even though these benefits are there, the market is confronted with difficulties as a result of the high manufacturing costs that are related with the investment casting method. Due to the fact that it requires a significant amount of time and labor, the technique could not be economically feasible for production of low volumes. Costs of materials, the intricacy of the design, and the amount of physical work all add to the total price. Investment casting is becoming more popular in the oil and gas sector, especially for thin-walled, near-net-shaped components that need little machining. This trend is being seen in the market, which is experiencing a growing trend in the usage of investment casting.

Automative casting is an effective method that creates long-lasting replacement components for a variety of applications, including equipment used in agriculture and construction and so on. In comparison to fabrication and machining, precision casting offers cost savings and faster lead times. An extensive number of metal casting quality checks are carried out by several metal companies to ensure that each and every component and part satisfies our stringent requirements and stringent tolerances. Team members that will collaborate with you include engineers, toolmakers, foundry and production specialists, and toolmakers who have extensive experience and a high level of expertise.

Automotive Investment Cast Parts

It is essential for the parts and components used in automobiles to be long-lasting in order to preserve their quality despite the effects of wear and tear and the environment. The most advantageous use of metal casting is in the manufacturing of intricate automobile parts. Casting processes that have been proved effective and refined over the course of decades of expertise are used by investment castings for automotive in order to produce castings that align with your specific design while maintaining precise tolerances.

Bottom Line

Today, investment castings future is bright with endless opportunities. They continue to be a driving force behind innovation in automobile engineering. They make it possible for manufacturers to push the limits of efficiency, reliability, and design.

Comments

Post a Comment