Enhancing Drug Delivery Systems: The Impact of Investment Casting in Pharma

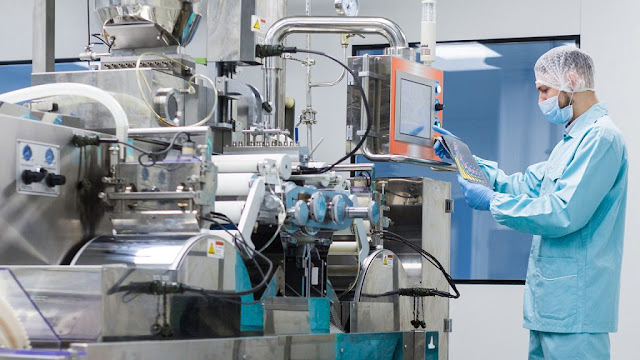

The pharmaceutical business places a significant emphasis on drug distribution, which has been the subject of several advances that have resulted in more efficient treatments and better results for patients. Modern approaches to the administration of drugs sometimes call for the use of intricate apparatus and processes, which may be time-consuming, costly, and prone to errors. Investment casting, on the other hand, is bringing about a revolution in drug delivery by making it possible to create drug delivery devices that are both precision and complex. Investment castings for pharma industry a lost-wax casting, is a manufacturing procedure that has been used for the duration of many centuries in order to make many components. Let us check the ways in which investment casting is being used in the pharmacological business.

Introduction To Drug Delivery And The Importance Of Innovation

The distribution of drugs is an extremely important aspect of the pharmaceutical business since it has a direct influence on the efficacy and efficiency of pharmacological therapies. The advancement of drug delivery technologies has the potential to change the healthcare industry by increasing the whole treatment experience, minimizing the number of adverse effects, and improving the results for patients. There are constraints associated with the conventional routes of medication delivery, such as oral pills or injections, which may be addressed by the use of new strategies.

Over

the course of the last several years, there has been an increasing focus on the

development of complex drug delivery systems that provide a controlled and

targeted release of drugs. Not only can these systems boost the therapeutic

effects of medications, but they also better ensure patient compliance and make

their lives more convenient. In the pharmaceutical industry, the use of

cutting-edge technology and materials allows for the development of innovative

delivery systems that maximize the bioavailability of drugs while

simultaneously minimizing their harmful effects.

Why the Need for Investment Castings Will Rise in the Medical Industry

There

are a number of factors that are driving the market for custom investment

castings in the medical industry. These factors include the rising demand for

medical professionals, various medical developments, and technology. The area

of technology moves at a breakneck rate, and the medical business is eager to

get on board with the most recent advances. For the purpose of making

prototypes and mass-producing the components that are essential for patient

care and curative technologies, these breakthroughs need the assistance of

manufacturers that specialize in investment casting.

The

requirement for fundamental investment-cast components, which frequently appear

in surgical rooms and medical centers, will increase in tandem with the

increasing need for healthcare.

The

median age of patients who need joint replacement treatments, such as knee and

hip replacements, has reduced and is now lower than it was before. The use of

investment-cast components is also used by surgeons in the replacement of

ankles, wrists, elbows, and shoulders. A few examples of implanted equipment

are shields, heat sinks, ultrasound machines, and devices that stabilize

injuries. Other examples include shields and heat sinks.

Investment

Casting May Be Used In Many Ways Within The Pharmaceutical Industry:

1. Manufacturing of complex and costly components:

The

process of investment casting enables the fabrication of elaborate and

sophisticated metal components with a notable degree of precision and accuracy.

2. Superior quality

Investment

casting is a manufacturing process that produces metal pieces of superior quality,

characterized by precise tolerances and polished surfaces. Precision is of

utmost importance in the pharmaceutical business, as it plays a critical role

in guaranteeing the safety and efficacy of pharmaceuticals and equipment.

3. Flexibility

Investment

casting has the advantage of material flexibility by enabling the use of

various metals and alloys. This versatility allows for the selection of

materials that align with the particular demands of the pharmaceutical

application. Various materials may exhibit diverse characteristics, including

but not limited to durability, resistance to corrosion, and compatibility with

biological systems.

Thus,

the high standards of investment

castings for pharma industry products have even been used for pump and

valve, pharmaceutical, fire fighting, and other general-purpose machinery, food

production machinery, earth moving and building machine components vehicle and

defense machineries, and they have been widely recognized to the complete

satisfaction of clients and customers based in a variety of countries. They

have a very unique standing in the marketplace and discipline as a result of

the high level of service and timely shipments that they provide.

Comments

Post a Comment